History of Henry & Sons

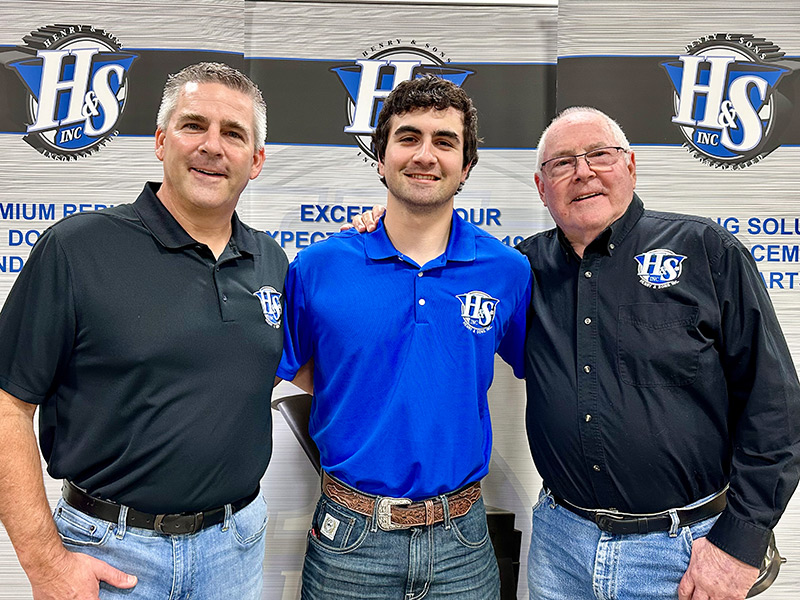

Henry & Sons was founded by Dave Henry in 1980. Dave has amassed over 10 years of experience in the food processing industry (including his work with Roger Reiser prior to establishing Henry & Sons). His vast knowledge and experience taught him two things in particular: customers’ requests are vitally important, and you must continue to improve technology and modernization in the industry. With this successful philosophy, Dave took a leap of faith and established Henry & Sons.

Henry & Sons was founded by Dave Henry in 1980. Dave has amassed over 10 years of experience in the food processing industry (including his work with Roger Reiser prior to establishing Henry & Sons). His vast knowledge and experience taught him two things in particular: customers’ requests are vitally important, and you must continue to improve technology and modernization in the industry. With this successful philosophy, Dave took a leap of faith and established Henry & Sons.

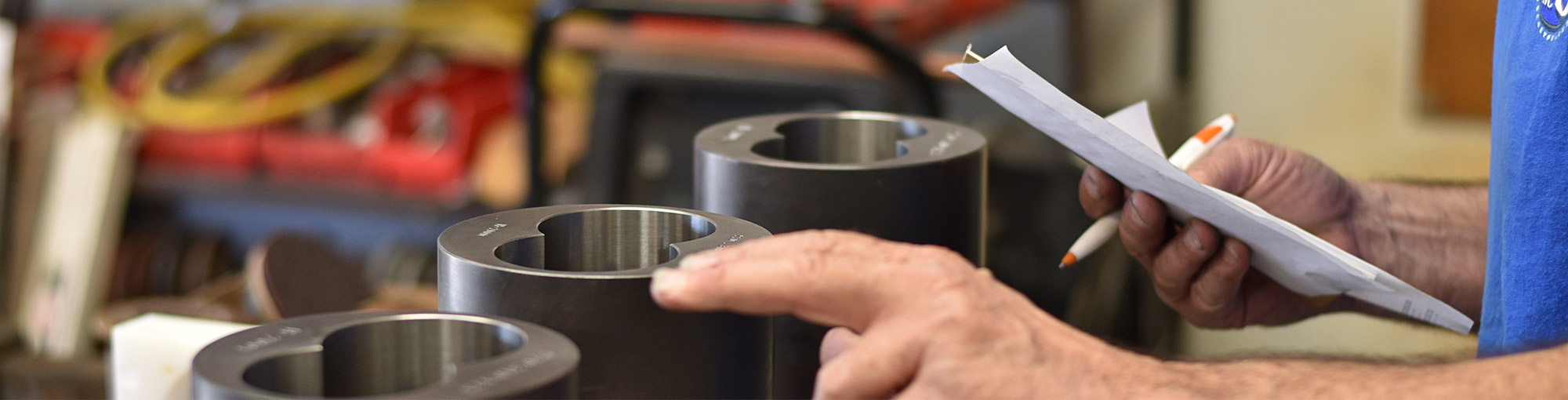

Dave’s original vision for Henry & Sons was to service, repair and overhaul his customers’ existing machinery. After only a few months, it was apparent there was a need for improved and alternative parts for the existing machinery, including the VEMAG stuffers.

After 44 years of evolving and growing, Henry & Sons has matured into a company that develops, engineers, and manufactures thousands of replacement parts for VEMAG vacuum fillers.

As a family business, each generation is taking the company to even higher levels of success and creativity. Dave’s son, Mark Henry, was raised in the business and is now the President of Henry & Sons. What is even more exciting is the addition of Morgan Henry, Mark’s oldest son and Dave’s grandson. Wisdom and knowledge are being passed down to each generation, making it a threegeneration (and counting) success story!

Important Timelines

1980: Henry & Sons was formed.

1986: Produced the first revolutionary Double-Screw & Housing.

1998: First AC-30 vacuum filler was designed and manufactured.

2018: Introduced the groundbreaking ERGO Double Screw Housing. This inventive design reduced the weight of the heavy 60+ pound housing to 30+ pound housing making it much safer to manage. Not only is the lighter housing safer for employees, but it also increases the parts’ durability and integrity.

2018: Henry & Sons released the all-new AC-30E vacuum filler with proven state-of-the-art technology. Henry & Sons has incorporated radical Dual-Servo technology, while making the AC30E the ONLY machine in this industry that offers a complete climate-controlled atmosphere inside its electronics cabinet. This allows the air to be heated, cooled, and dried while being recirculated in this space, thus increasing the lifespan of the electrical components.

2021: The release of the newest innovation, the patented Zero Contact Double Screw & Housing design. This cutting-edge technology completely changes the industry and allows customers to exponentially extend the lifespan of their investment. We are experiencing astonishing results while increasing weight control, reducing product waste, and providing enhanced, consistent, and dependable product appearance.